Manufacturing companies have long tried to drive increased customer value and faster time to market through improved operations, quality and logistics efficiency initiatives. At the heart of the most effective product development and manufacturing efficiency programs is actionable data being collected and analyzed to connect the design process through production and distribution.

To obtain optimal value, there are challenges to integrating and leveraging legacy machines that were not designed with today’s built-in communication modules that now provide seamless connectivity and interoperability. Creating a network of interconnected devices requires a means for legacy devices that are not IP-based to connect without having to bear the cost of a full Ethernet or Wi-Fi interface and protocol stack. Fortunately there are cost effective solutions available today.

Modern data enablers in manufacturing such as Internet of Things (IoT) technology, and analytics and AI solutions have been deployed to create game-changing efficiencies and business models. The benefits and areas of improvement are substantial. According to a recent study, several areas of improvement a typical enterprise focuses on, including Industrial Automation detailed below, are being enabled and positively impacted by AI and analytics solutions that are driven by IoT as well as other data sources:

Industrial Automation and IoT

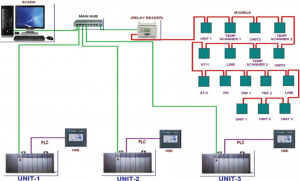

Industrial Automation includes the use of various devices like shop floor and data center compute resources, PLC’s, robots, other monitoring and control devices for handling, as well as controlling different processes and machines. Integrating those IoT devices into collecting important data is fundamental but not sufficient.

Industrial automation companies that continue to adopt IoT strategies stand the best chance to overcome organizational, process, data and system silos by automating the collection of data across divisions and operations. They’ll be positioned to better analyze and utilize all that data helping to ensure more efficient and profitable operations. To get a little more granular, the following impacts can be driven by deployment of an end to end IoT strategy:

- Enhanced efficiency

- Higher accuracy

- Cost-optimization

- Quick process completion

- Lower power needs

- Reduce errors

- Manufacturing control

Top Use Cases

- Predictive maintenance – uses analytics to determine the condition of assets. It usually combines sensor/IoT readings, external data sources, and performs predictive analytics. The goals are to increase asset useful life and decrease downtime. The savings and payback are substantial.

- Quality inspection & assurance – there are various ways to do AI-based quality inspection, and automated optical inspection is typically very important. Data collection is frequently enabled by IoT solutions. Reduction in test time and scrap yields great savings.

- Manufacturing process optimization and automation – autonomous assets can replicate human tasks in the manufacturing process and saving costs while improving accuracy. Utilizing AI is somewhat complex but the payback and cost impacts can be substantial.

- Supply chain optimization – using AI tools to improve inventory management by leveraging predictive analytics to reduce inventory planning time, minimize inventory cost, optimize repairs, and find optimal reorder points.

- Cybersecurity – this critical process is typically AI-driven and protects company compute and controls assets. Detecting threats of cyberattacks in real time is essential to continuous operations and is also often part of a larger manufacturing enterprise cybersecurity strategy.

- Automated physical security – physical detection of threats requires real-time surveillance to detect physical security threats and/or potential safety hazards.

Priorities and Where To Begin

With all the areas of improvement that are possible, it is critical to determine and prioritize use cases based on end-to-end value and company-wide benefits. With the IT and OT environments becoming more complex every day, the goal must be to stack-rank use cases based on these considerations:

- Base use case priorities on predetermined KPIs that are linked to business value optimization.

- Determine the ability of current and future deployed technology to support these use cases, and include both the current and near term future technology stack and applications specific to those use cases. Factors that make constructing a scalable technology stack challenging in any industrial environment include the complexity and vintage of the deployed industrial-automation tools and systems, the variety of sensor subsystems, legacy machines that are still unconnected and not being leveraged.

- Determine and incorporate data expertise in the beginning of any implementation process – data scientists need to work with design and process engineers to ensure that the data can be both collected accurately at source and aggregated into the right location at the right time.

- Most start with a pilot project with multi-discipline teams and closely monitored deliverables, metrics and milestones.

- For the long term, create and align IT and OT roadmaps with broader business goals and current and future hardware and software technologies.